Connect PLC and I/O point

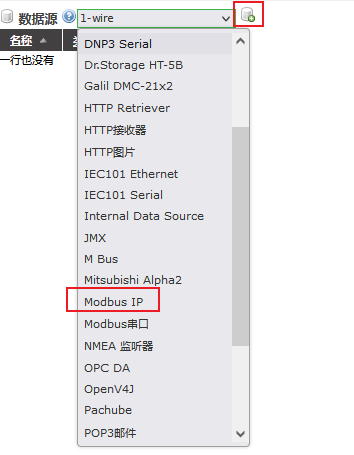

- Click the following icon for Data source in the upper left corner

of the main interface:

Figure 1. Data source

- Select Modbus IP as the data source type and click

Add:

Figure 2. Select Modbus IP as Data Source

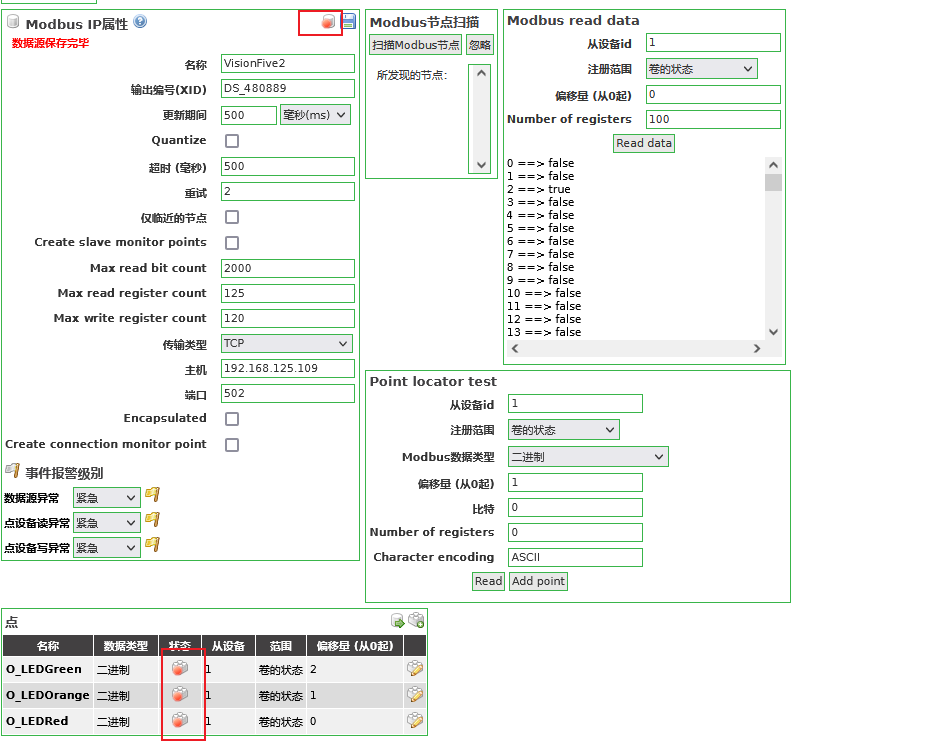

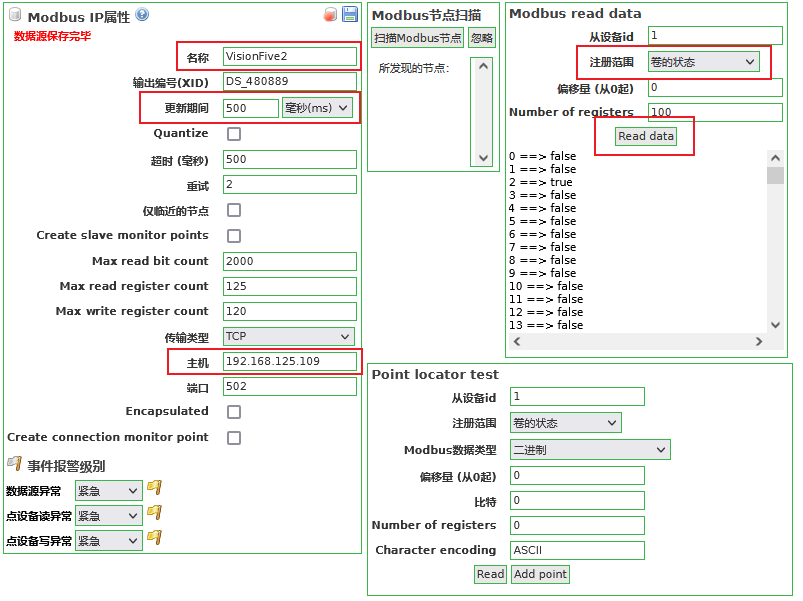

- In Modbus IP, set the name, select the appropriate update time, fill in the host IP, and

save the data source. Then select the value type to be read in the registration range of

Modbus read data on the right and click Read Data to read the current

value of the corresponding type quantity of the corresponding host through Modbus:

Figure 3. Modebus IP Settings

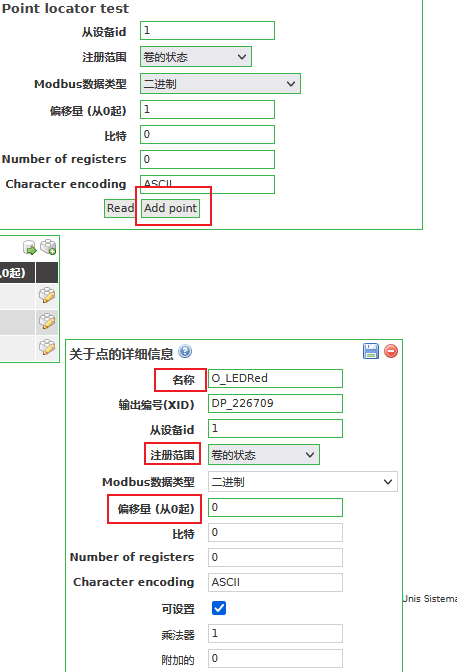

- Then click ‘add point’ on the Point locator test, enter the

Name of the data Point (preferably the same as ), the offset (starting at 0, corresponding to 0.0 in PLC), and save:

Figure 4. Point Settings

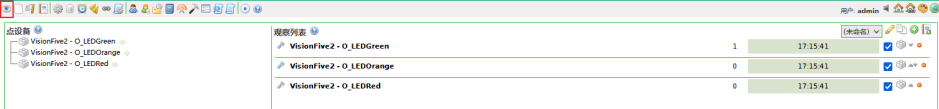

- Then activate each point and the device, that is, click the observation list of the first

icon in the upper left corner to view the value of each data point of the device in

real-time:

Figure 5. Data Point Values